1. Divided by function, tangential flow filtration is mainly used for:

Concentration, clarification, dialysis, purification, heat source removal, buffer replacement, desalination, cell harvest clarification, etc.

2. According to the purpose, tangential flow filtration is mainly used for:

Monoclonal antibodies/biosimilars, recombinant proteins, vaccines, blood products, liposomes, small molecules (insulin, peptides, polysaccharides, monosaccharides, etc.), new treatments (plasmids, virus vectors, etc.), traditional Chinese medicines, chemical medicines, etc.

Second, the classification of filtering

1. Ultrafiltration membrane: 1kD-1000kD, with a membrane pore size of 0.001-0.10um

2. Flux and membrane area

General expression of flux: literes/(square meter× hour)

Lmhl/(m2× hour)

Third, tangential flow filtration membrane

Note: the flux of tangential flow filtration membrane is related to the pore size. Generally speaking, the larger the pore size, the higher the flux under the same conditions. The flow rate in the table is relative to the polyethersulfone membrane with the same pore size.

2. Selection of tangential flow filtration membrane

Material:

-Different membranes have different protein adsorption, usually: polysulfone > polyethersulfone > cellulose membrane, extremely low: Ultracel (composite regenerated cellulose) < 0.1g/m2;; Low: Biomax (modified polyethersulfone membrane) < 0.2g/m2.

-Chemical compatibility

Aperture, 3-5 times principle

-There should be a difference of three to five times between the selected pore size and the trapped molecules, and a difference of more than three to five times between the separated substances. For example, the molecular size of the monoclonal antibody is 150kD, and a 30kD membrane is usually used for concentration.

4. Optimal design of membrane package

(1) the role of the screen in the runner:

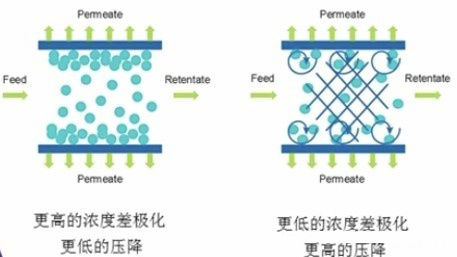

① Soft turbulence is generated on the membrane surface to control the concentration polarization on the membrane surface.

② Hydraulic resistance leads to higher pressure drop.

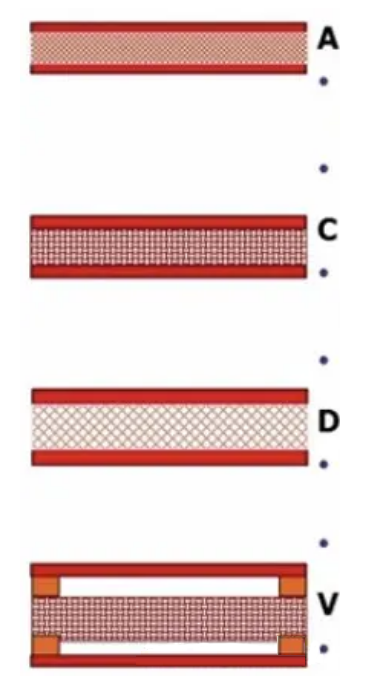

② Selection of four kinds of screens: A, C, D and V.

Ⅰ A screen (dense)

Maximum pressure drop/maximum mass transfer efficiency at unit tangential flow velocity

15-20psi,2.6-4.3L/min/m2

Used for clean, low concentration and low viscosity feed liquid.

Ⅱ C screen (rough)

Moderate pressure drop at unit tangential flow velocity

5-10psi,2.6-4.3L/min/m2

Used for clean, medium concentration and low viscosity feed liquid.

Ⅲ D screen (rough)

Medium and low pressure drop at unit tangential flow velocity

2-6psi,5-6L/min/m2

Used for high concentration and high viscosity feed liquid.

Ⅳ V screen (suspended)

Lowest pressure drop at unit tangential flow velocity

0.5-2.0psi,2.6-4.3L/min/m2

It is used to concentrate the feed liquid with high solid content, ultra-high concentration and high viscosity.